Getting Dilution Right: How Proper Mixing Boosts Cleaning Power and Cuts Costs

In a busy industrial setting, dilution errors occur more often than we’d like to admit.

Over-mixing wastes money, wears away surfaces, and causes skin issues for the team. Under-mixing means the job isn't done right the first time, requiring twice the work.

When facilities rely on concentrated cleaning solutions, precise mixing is one of the easiest ways to improve results without increasing spend.

The Reality of Chemical Ratios

Cleaning products balance surfactants and solvents to remove grime from surfaces. When that balance is off, the product can’t perform its intended function, and safety risks arise.

The Risks of Over-Mixing

Solutions that are too strong irritate your crew's skin and eyes and leave sticky or slippery residues that attract dirt. Over time, those harsh levels will eat away at your equipment finishes and floor seals, leading to expensive repairs.

The Problem with Under-Mixing

If the mix is too weak, it won't have the muscle to lift grease or carbon. Your team ends up doing two or three passes to get a result that should have taken one. In a production environment, a weak mixture can affect regulatory compliance, slow turnaround times, and increase water and energy bills.

Understanding SDS and Label Instructions

Under WHMIS, every employer must ensure that Safety Data Sheets (SDS) are readily accessible and that everyone on the floor fully understands the hazards associated with the chemicals they handle every day.

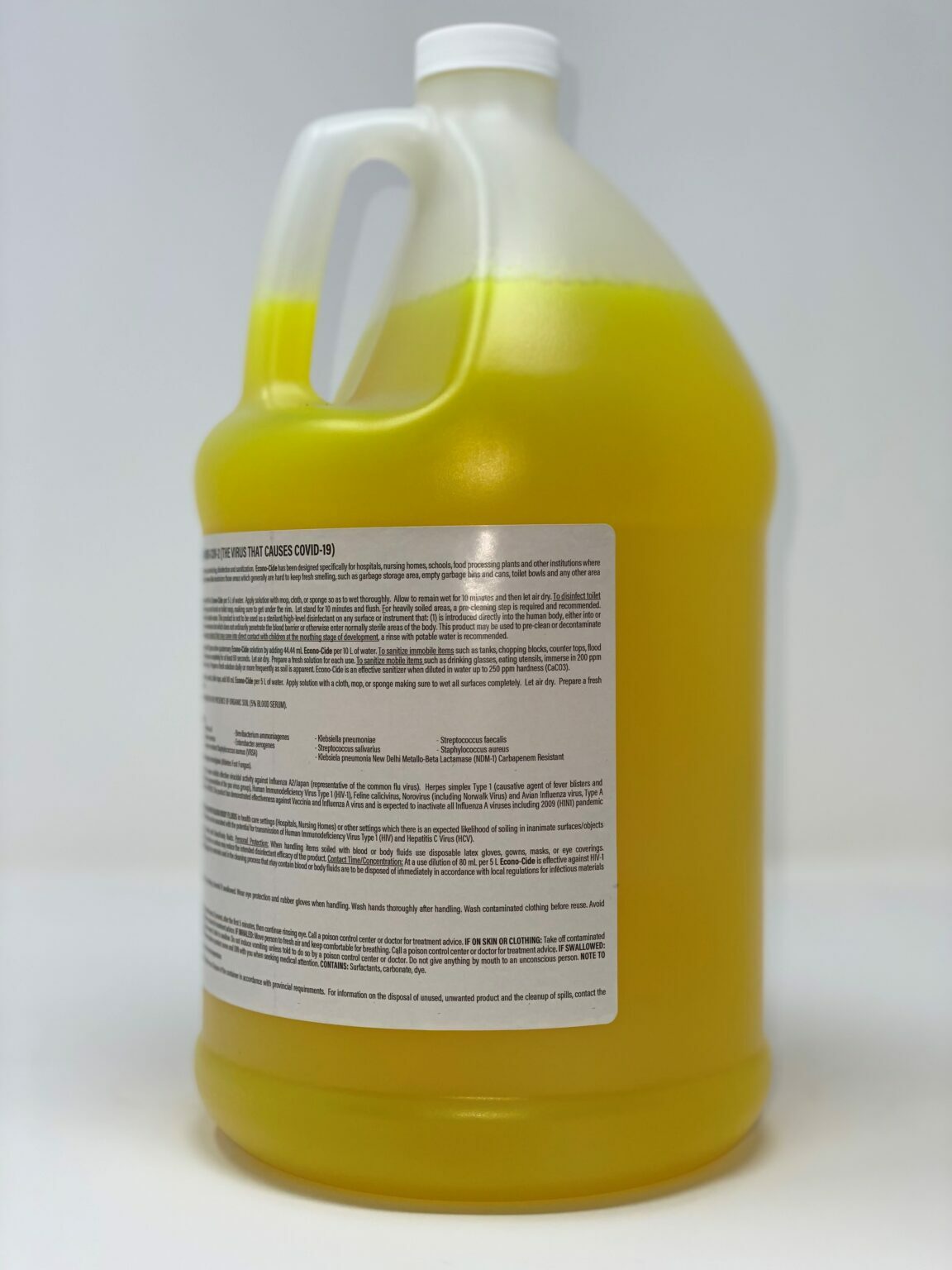

The SDS for Econo-Clean applies to the pure concentrate. The SDS recommends PPE such as gloves and eye protection, when handling the concentrate, and storage guidance appropriate for an alkaline cleaner. When diluted with water as recommended, Econo-Clean becomes much safer to use, compared to the concentrate. These details help teams understand how to mix the product and handle it safely from delivery to disposal.

Interpreting Ratios and Symbols

Dilution ratios are usually expressed as parts water to parts concentrate, or as millilitres per litre. Getting these right is the easiest way to prevent product waste and ensure consistent results.

Before you start mixing, check for the safety pictograms on the label. These icons provide an instant visual warning about factors such as corrosivity and eye irritants so that you can prepare accordingly.

Tools and Best Practices For Mixing

Getting your dilution ratios right is a lot easier when you have the right tools and a solid routine in place. Typically, the best setup for your facility depends on how much cleaning you do and who handles chemicals.

Choosing Your Method: Manual vs. Automatic

If you’re mixing by hand, you’ll want to rely on measuring cups, proportioning bottles, or mop buckets with clear fill lines. These tools work well as long as the team is fully trained and follows the same steps every time.

Automatic systems, such as wall-mounted dispensers or scrubber injectors, deliver the same ratio every time, effectively eliminating human error and saving significant time.

Staying Safe with Chemical Compatibility

Never mix different chemicals. Combining acids with alkaline cleaners, or mixing anything with bleach, can be incredibly dangerous, often releasing toxic gases or neutralizing the cleaners so they don't work at all.

Dilution Control as a Core Cleaning Standard

Getting dilution right is one of the most controllable factors in any cleaning program. When facilities follow SDS guidance, train teams to interpret labels, and use reliable mixing tools, concentrated cleaners like Econo-Clean perform as intended without increased risk or waste.

Precise dilution supports safer workplaces, stronger cleaning results, and long-term cost control across

industrial operations.

SOURCES

https://www.ccohs.ca/oshanswers/chemicals

https://canadianchemistry.ca/what-we-do/chemicals-management/