Industrial Degreasing in Heavy Manufacturing: Managing Oils, Metals, and Machinery Safely

Heavy manufacturing environments routinely accumulate oil, metal dust, carbon, and other residues on production floors and equipment. These by-products are an unavoidable result of machining, stamping, cutting, and fabrication processes.

If left unaddressed, buildup can interfere with machine performance, accelerate wear, and increase safety risks for workers. Effective degreasing is therefore a routine maintenance task that supports equipment longevity and safer operations.

This article outlines common degreasing challenges in industrial settings, compares solvent-based and water-based cleaners, and reviews safe application and disposal practices relevant to Canadian facilities.

Common Degreasing Challenges in Heavy Manufacturing

Industrial environments generate contaminants that tend to bond tightly to metal surfaces. The most common include:

- Lubricants from bearings, gears, and moving assemblies

- Coolants remaining after machining cycles

- Metalworking fluids that attract dust and carbon residue

Over time, these substances reduce surface efficiency and can contribute to corrosion or mechanical wear. Consistent, targeted degreasing helps maintain equipment condition and reduces unplanned downtime.

Solvent vs. Water-Based Degreasers

Different types of degreasers interact with residues, surfaces, and workplace safety requirements in distinct ways. Understanding these differences helps facilities select products that align with their operational and regulatory needs.

Solvent Degreasers

Solvent-based cleaners are effective at dissolving heavy petroleum-based grease and thick buildup. They act quickly, which can be useful for certain applications, but they also introduce considerations such as:

- Strong fumes require adequate ventilation

- Increased handling and storage precautions

- Stricter disposal requirements

Some solvent formulations may also face limitations under Canadian environmental regulations, depending on their chemical composition.

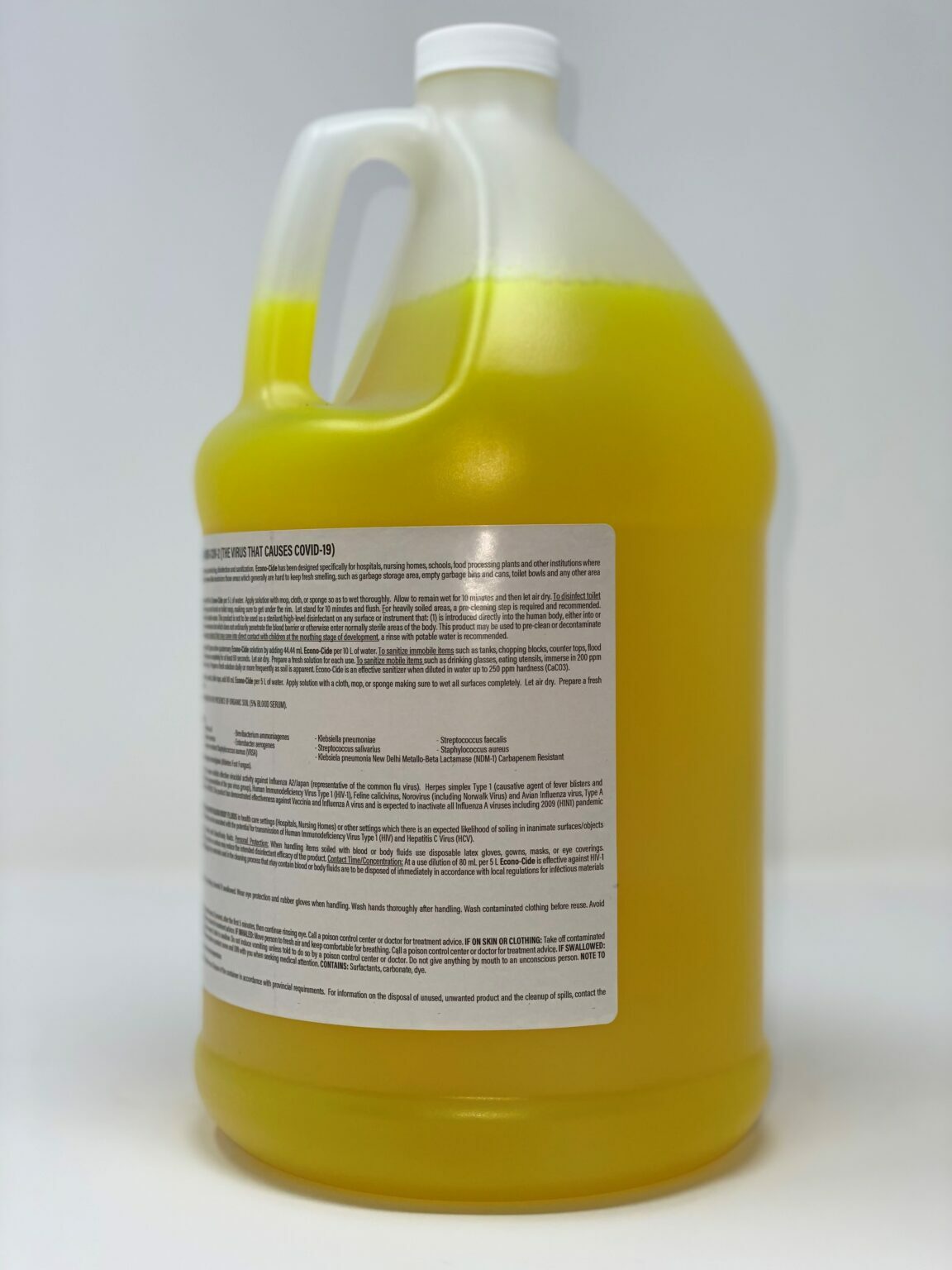

Water-Based Degreasers

Water-based degreasers rely on detergents, surfactants, and alkalinity to loosen oils and debris from surfaces. These products are commonly used in facilities looking to reduce vapour exposure and environmental impact.

Typical characteristics include:

- Lower airborne emissions compared to many solvents

- Broader surface compatibility

- Alignment with CEPA-related environmental considerations

Regardless of product type, facilities should always follow the Safety Data Sheet (SDS) for guidance on ventilation, protective equipment, and handling procedures.

Safe Application and Disposal Practices

Effective degreasing depends not only on product selection but also on proper application and disposal methods.

Dilution and Dwell Time

Using the correct dilution ratio is essential. Applying cleaner at the appropriate strength and allowing sufficient dwell time helps break down residue without damaging surfaces. Different applications—floors, tools, or machine components—often require different contact times, which should be confirmed through SDS guidance.

Mechanical agitation, such as brushing or parts washers, can further assist with removing stubborn buildup.

Spill Containment and Wastewater Handling

Canadian facilities are required to manage degreasing runoff carefully. Wastewater should be collected in designated containment systems, with solids filtered out before disposal through approved channels. Proper handling reduces environmental risk and supports regulatory compliance.

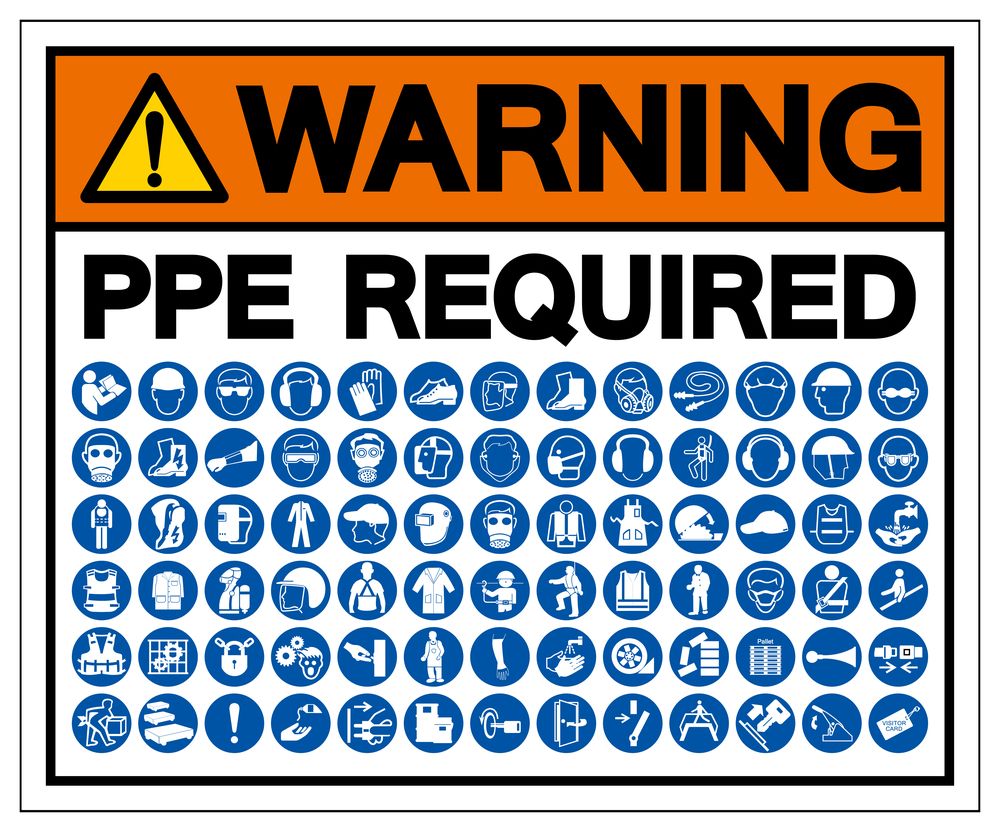

PPE and WHMIS Training

Worker safety depends on proper training and awareness. WHMIS programs help employees understand:

- Label and SDS information

- Potential chemical hazards

- Required personal protective equipment

- Procedures for spills or accidental exposure

Supporting Cleaner, Safer Manufacturing Environments

Routine degreasing, combined with clear application procedures and responsible disposal practices, plays an important role in maintaining industrial facilities. Water-based and solvent-based cleaners each have appropriate use cases, and the right choice depends on operational needs, safety considerations, and regulatory requirements.

A thoughtful approach to degreasing supports equipment performance, workplace safety, and long-term facility reliability.