Sanitation Standards in Food Processing Plants: Choosing Safe, Compliant Industrial Cleaners in Canada

Food processing facilities rely on strong sanitation programs to keep operations safe, compliant, and efficient. The Canadian Food Inspection Agency (CFIA) and the Safe Food for Canadians Regulations set strict sanitation rules that help protect consumers, staff, and production equipment from contamination.

Keep reading to learn how CFIA and HACCP standards shape cleaning protocols, what defines a food-safe cleaner, and how to maintain a spotless facility in your day-to-day.

Understanding CFIA and HACCP Cleaning Requirements

Every Canadian food plant operates under the watchful eye of the CFIA, an organization that ensures facilities adhere to strict hygiene and safety protocols. Understanding and implementing these standards is crucial for maintaining a safe and compliant operation.

These guidelines, often paired with Hazard Analysis and Critical Control Point (HACCP) programs, focus on preventing contamination before it starts. That means cleaning every surface, drain, and conveyor to remove residues without leaving harmful chemicals behind.

A key part of CFIA and HACCP compliance is using cleaners that are rinseable, effective, and compatible with the equipment they’re meant for:

- Rinseability ensures that no detergent residues remain on surfaces that come into contact with food.

- Use alkaline cleaners on stainless steel and greasy equipment because they break down fats and proteins quickly.

- Neutral cleaners are safer for delicate metals, painted areas, and food contact surfaces that require a gentler touch.

Selecting Food-Safe Industrial Cleaning Supplies

Before you bring any cleaner into a food plant, it must meet strict criteria to be considered food-safe. The product must be non-toxic, residue-free, and biodegradable once rinsed. These features help keep food contact areas safe while supporting environmental sustainability.

Many facilities rely on Clean-in-Place (CIP) or Clean-out-of-Place (COP) systems to make sanitation efficient and consistent:

- CIP systems circulate cleaning solutions through equipment, such as tanks or pipes, without requiring disassembly or downtime.

- COP involves removing smaller parts for soaking or scrubbing in dedicated wash stations.

When sourcing cleaning chemicals, confirm that Safety Data Sheets (SDS) and bilingual WHMIS labels are available and compliant with Canadian regulations. Econo-Chem provides transparent SDS documentation with pH data, helping operators stay compliant with CFIA.

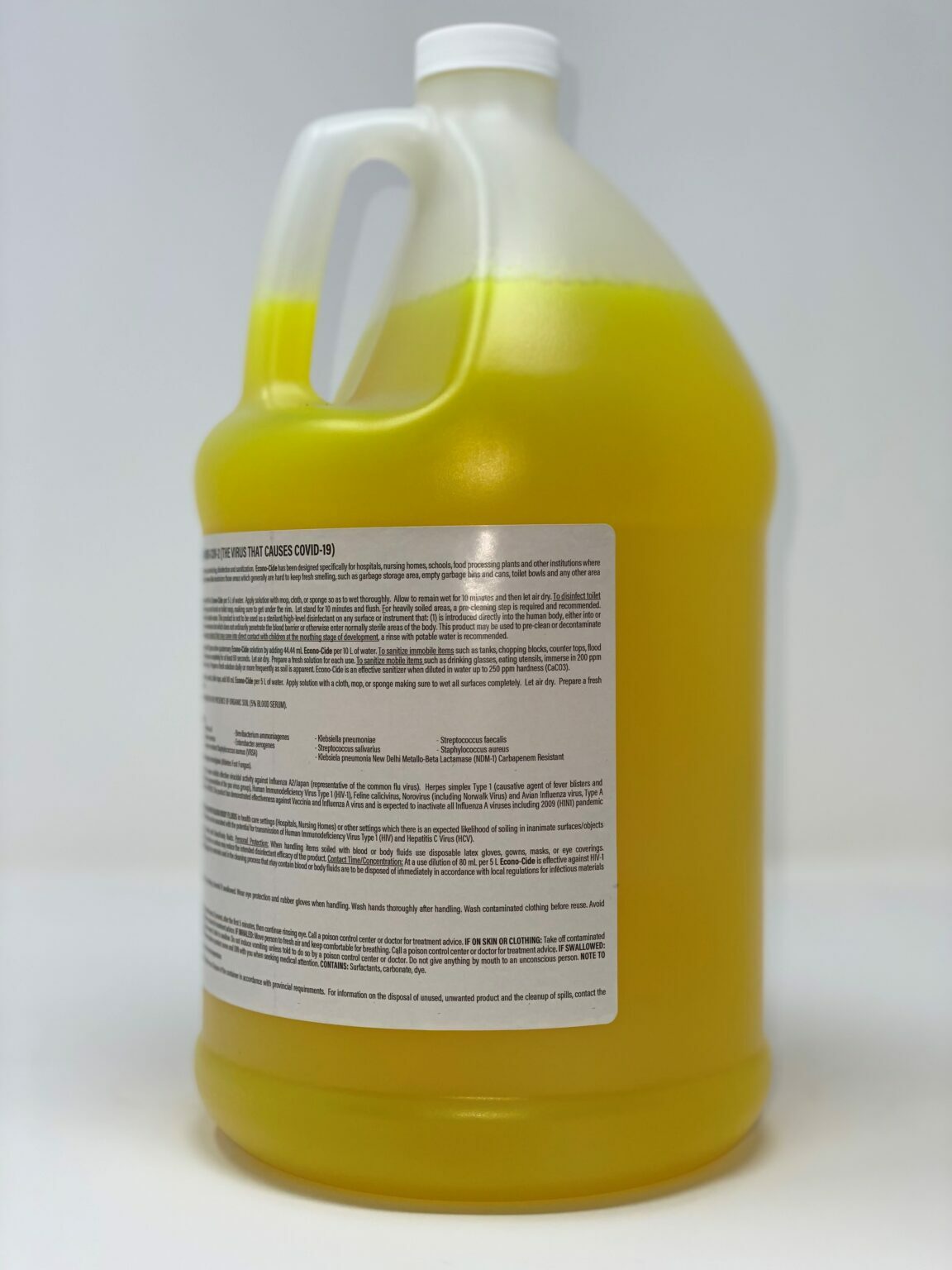

Check it out:

LONO from Health Canada, approving Econo-Clean for use in food processing areas.

Best Practices for Daily and Deep Cleaning

Clean and sanitize prep areas, food contact surfaces, and conveyors daily, and schedule weekly or monthly deep cleans for drains, ceilings, and hard-to-reach spaces.

Keeping a detailed checklist makes the process faster and ensures you don’t overlook anything during busy production periods:

- Remove all visible food debris and residues

- Apply the diluted cleaning solution

- Scrub and rinse thoroughly with potable water

- Sanitize and allow surfaces to air dry before restarting production

- Document cleaning times, products used, and the responsible staff member

Handle concentrated products carefully by following proper dilution guidelines. Econo-Chem’s SDS data notes that cleaners like the pure concentrated

Econo-Clean (pH 12–14) require labelled containers, safe storage away from acids, and protective gear during mixing to protect workers and maintain compliance.

Setting the Standard for Food-Safe Facilities

By following CFIA and HACCP standards, using verified food-grade cleaners, and maintaining a consistent sanitation routine, you play a crucial role in ensuring your facility meets Canada’s expectations for safety and compliance.

For reliable, CFIA-approved solutions, explore

Econo-Chem’s Industrial Cleaning Supplies, trusted by Canadian food processors that prioritize safety, quality, and sustainability.