Best Practices for Cleaning Stainless Steel Milking Parlour Walls

Milk quality depends on cleanliness, and that begins in the parlour. Stainless steel parlour walls offer a smooth, durable surface that supports sanitation but isn’t maintenance-free. Without regular care, even high-grade steel can become a breeding ground for bacteria or start to corrode.

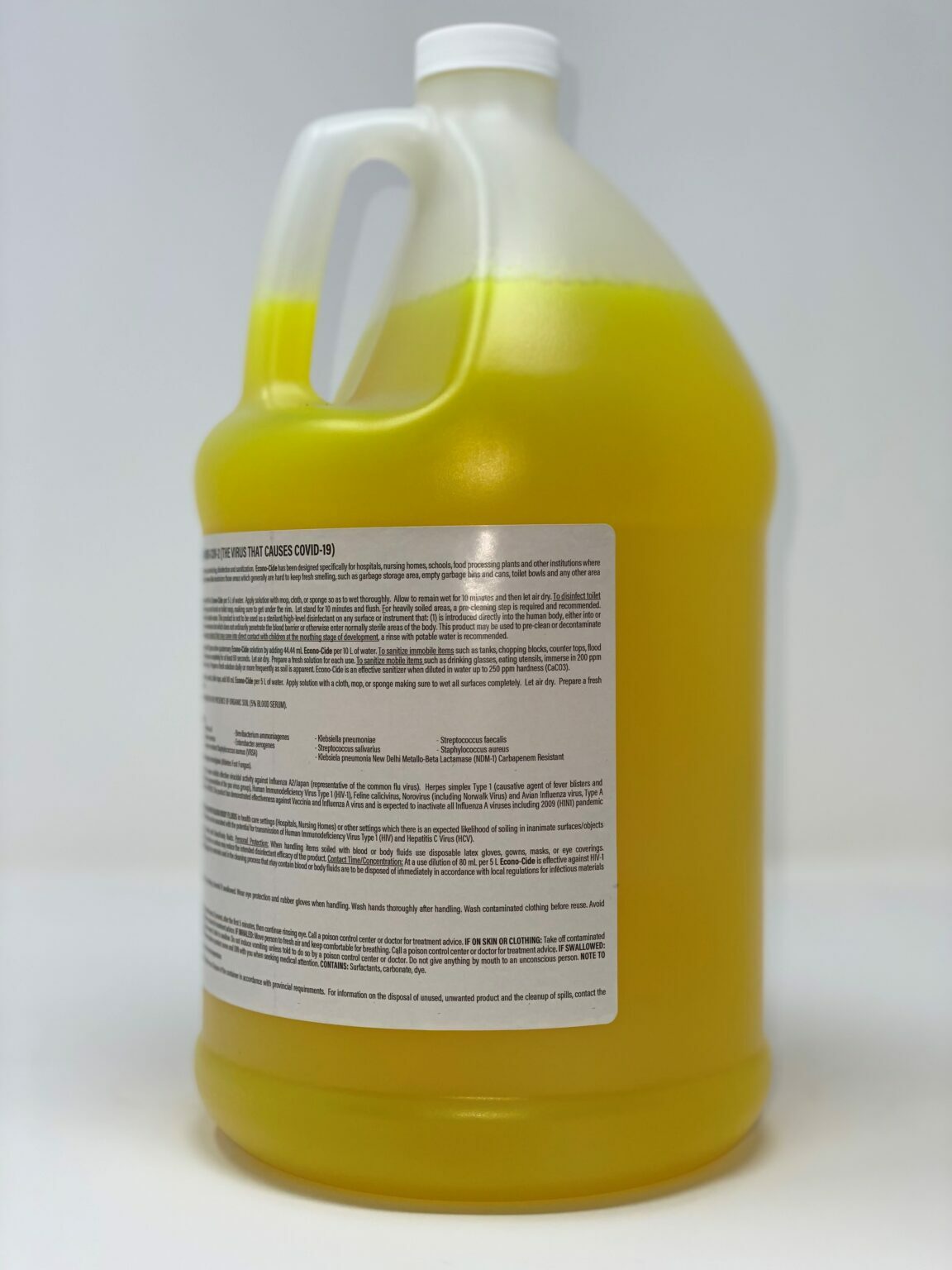

Keep reading to learn how to clean stainless steel parlour walls using a rapidly-biodegradable, food-safe cleaner like

Econo-Clean.

Why Proper Cleaning Matters

Even stainless steel has its limits when exposed to constant moisture, organic matter, and chemical residues. Keeping surfaces clean protects your equipment and your animals in more ways than one:

- Prevent corrosion and pitting: Milk residues and harsh chemicals can break down its protective layer, leading to permanent surface damage.

- Eliminate pathogens and biofilms: When milk residue dries on walls, it creates a sticky film that shelters bacteria. Over time, this biofilm becomes harder to remove and compromises sanitation.

- Meet regulatory standards: Clean parlour walls are a requirement. Health Canada and CFIA standards demand strict hygiene in all milk-handling areas.

- Protect your investment: Daily maintenance extends the life of your milking equipment and infrastructure. Clean walls are less likely to degrade, reducing repair costs over time.

Pre-Cleaning Preparation

Before scrubbing your parlour walls, prepare the area carefully to make the cleaning easier and more effective.

Inspect the Surface

Check for dried-on milk, discolouration, or scratches that might collect buildup. Seams and corners are especially good at hiding grime.

Remove Loose Debris

A dry brush or air blower helps remove dust, cobwebs, and dried solids before adding moisture.

Suit Up for Safety

Proper ventilation, chemical-resistant gloves, and safety goggles go a long way toward preventing accidents.

Cleaning Instruments

Use a low-pressure sprayer, non-metallic brushes, and food-grade cloths or sponges.

Step-By-Step Cleaning Process

Are you using the right cleaner? The right tools and formula make all the difference. Follow this sequence to keep your stainless steel parlour walls in top shape.

- Use proper tools: Nylon or soft-bristle brushes prevent scratching. Always scrub in the same direction as the metal grain.

- Prep the solution: Dilute your biodegradable cleaner according to label directions (typically 1:30) in warm water (40–60 °C) to break down fats and proteins effectively.

- Apply: Spray from the top down and let it sit for 3 to 5 minutes, giving it time to break down organic matter.

- Wash and rinse: Scrub, rinse with potable water, and check for streaks or leftover residue.

Post-Cleaning Inspection and Drying

Cleaning isn’t done until the walls are dry and spotless:

- Do a final inspection: Use a bright light to check for streaks, spots, or stubborn grime. If anything is left behind, repeat with a damp cloth.

- Dry the walls: Use lint-free towels or a low-pressure air system to dry every surface. Moisture invites bacteria, so don’t let it linger.

Professional Results Backed by Econo-Chem

Keeping stainless steel parlour walls clean supports milk safety, herd health, and equipment performance. With the right prep, technique, and tools, cleaning becomes an efficient routine that protects your operation while maintaining regulatory compliance.

References

- CFIA Good Manufacturing Practices for dairy processors: inspection.canada.ca

- Evaluation criteria for dairy-processing equipment cleanliness: inspection.canada.ca

- Biofilm formation on dairy-industry stainless steel: pmc.ncbi.nlm.nih.gov

- Protein residue and biofilm attachment: qualitru.com

- Corrosion risks of acids on stainless steel: sciencedirect.com

- Nitric acid passivation of stainless steel: nickelinstitute.org

- Econo-Clean biodegradable cleaner specs: econo-chem.com

- Dairy-equipment cleaning safety and PPE: agriculture.institute

- Milking-parlour equipment prewash protocols: agproud.com

- Scrubbing with the grain best practice:

realsimple.com