What It Means to Meet the WHO’s 75% Isopropyl Standard in Hand Sanitizer

Hand sanitizer is a frontline defence in hygiene, especially in settings where soap and water aren’t readily available. The World Health Organization (WHO) guidelines ensure that alcohol-based hand rubs kill germs and protect public health.

One of the WHO’s standards is Formulation II, which uses 75% isopropyl alcohol (v/v). But what does it take to meet that standard, and why is it so important?

Keep reading to learn how 75% isopropyl works, the safe ingredients, and why it matters for businesses and facilities.

What Is WHO Formulation II?

WHO Formulation II is one of two recommended recipes for making effective hand sanitizers. It provides a reliable standard in situations where commercially produced sanitizers may be scarce.

The

typical composition for one litre is as follows:

- Isopropyl alcohol (99.8% purity) at 75% v/v

- Hydrogen peroxide (3%) at 0.125% v/v

- Glycerol (98%) at 1.45% v/v

- Distilled or boiled-and-cooled water to reach the final volume

The hydrogen peroxide inactivates spores in the mixture or containers, while glycerol acts as a humectant to reduce drying effects.

Why 75% Isopropyl Alcohol Matters

The efficacy of alcohol-based sanitizers depends heavily on the concentration of the active alcohol. Too low, and it can't reliably inactivate viruses or bacteria. Too high, and it may evaporate too rapidly to act effectively.

A 75% isopropyl (v/v) concentration is within the range that balances potency and contact time. Tests of the WHO-recommended formulation show equivalent microbicidal efficacy in laboratory settings for hygienic hand antisepsis.

In one evaluation, even a

3 mL application with 75% isopropyl achieved the required bacterial reduction in 30 seconds. Impure alcohol or the wrong grade can compromise performance.

Best Practices for Use and Safety

Meeting production standards is only half the battle — safe use ensures effectiveness in everyday contexts:

- Use an alcoholmeter or hydrometer to verify the final concentration

- Mix in a ventilated, flame-safe area

- Label bottles appropriately to prevent misuse

- Store in cool, well-ventilated rooms

- Use within 72 hours of production or keep bottles sealed

- Don’t add fragrances or other chemicals unless validated, as they may interfere with the germicidal action or cause skin sensitivities

Why This Matters for Businesses and Facilities

In settings such as healthcare facilities, schools, offices, or manufacturing plants, a sanitizer that meets WHO standards offers assurance and regulatory confidence.

Facilities that produce or distribute sanitizer, such as pharmacies and

hospitals, must ensure reliable disinfection. Businesses using sanitizer that meets the 75% isopropyl standard reduce risks of outbreaks, support employee health, and ensure compliance.

When supply chains break down, having the ability to produce compliant sanitizer in-house keeps your operations steady and resilient.

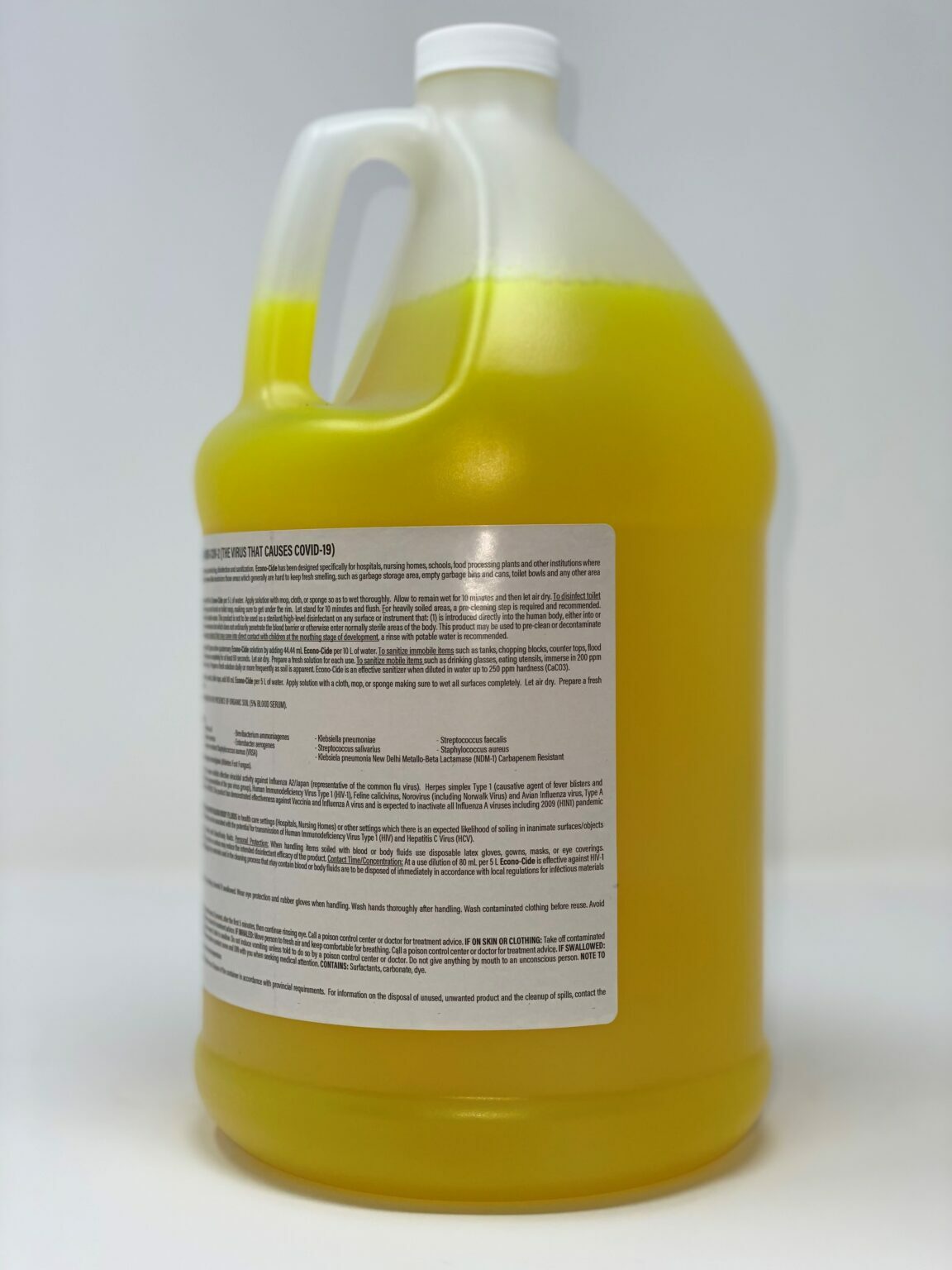

Trust Econo-Chem for Verified WHO-Approved Solutions

Following the WHO’s 75% isopropyl guideline with Formulation II requires accuracy, high-grade components, and proper verification. When prepared correctly, the result is a product that remains effective, safe, and dependable.

For organizations, upholding these standards shows genuine responsibility and care. It ensures dependable protection, builds product trust, and offers peace of mind when health risks are at their peak.