Removing Pesticide and Herbicide Residues from Farm Machinery

Farm machinery works hard, often in some of the harshest conditions. Over time, it builds up layers of grease, diesel, dust, and chemical residues from pesticides and herbicides.

These residues can be corrosive, unsightly, pose safety risks, and affect crop protection efforts during future applications.

Keep reading to learn the best practices for removing pesticide and herbicide residues from agricultural equipment using a structured, efficient cleaning approach.

Preparation and Safety

Before you begin, choose a well-ventilated area far from crops, livestock, or water sources to prevent contamination.

Wear proper protective gear — gloves, eye protection, and clothing that shields you from splashes and residue.

Collect any used rinse water responsibly, especially if cleaning sprayers or tanks that carried regulated chemicals.

Check the equipment’s service manual for any sensitive parts or electrical systems to avoid during

cleaning. Disconnect power when necessary and ensure moving parts are safely locked out.

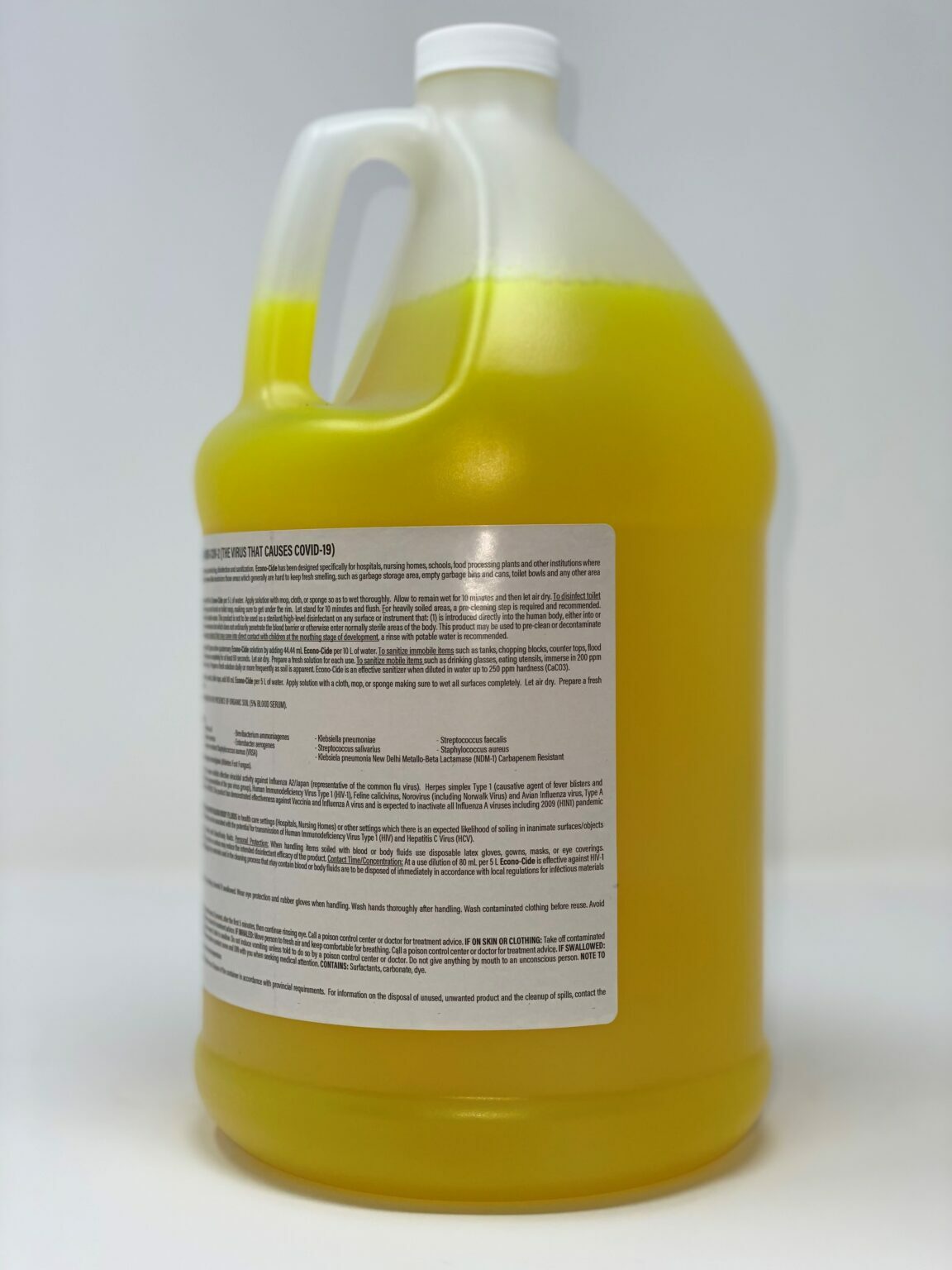

Econo-Clean Dilution Ratios

Using the right cleaner-to-water ratio ensures a thorough clean without wasting product. Econo-Clean, a heavy-duty industrial cleaner, adapts easily to different jobs with flexible dilution options:

- Heavy-duty (diesel, grease, engine gunk): Use a 10:1 cleaner-to-water ratio for maximum degreasing power, ideal for engines, undercarriages, and heavily soiled components.

- Moderate-duty (pesticide & herbicide residue): For tanks, nozzles, booms, and surfaces exposed to spray chemicals, dilute Econo-Clean 20:1 to 30:1. This concentration breaks down chemical films without leaving behind residue or harming sensitive parts.

- Light maintenance: Use a 120:1 dilution for regular wipe-downs, preventative maintenance, and cleaning of cab interiors or control panels.

Step-by-Step Cleaning For Farm Machinery

Here’s how to safely remove built-up residues from your farm equipment.

Step #1: Application

Apply the diluted cleaner using a sprayer, pressure washer, or brush, targeting high-contact zones like booms, spray lines, filters, nozzles, and tank interiors; these are where residue builds up most.

Step #2: Dwell Time

Let Econo-Clean sit for 5 to 10 minutes (depending on the level of buildup). This process allows the solution to break down grease and chemical bonds without scrubbing too aggressively.

Step #3: Agitation

Use a soft-bristle brush or cleaning pad to loosen residue from stubborn areas. For internal components like tanks or lines, circulate the cleaning solution for even distribution.

Step #4: Rinse

Rinse completely with clean water; a pressure washer will give you better coverage. For internal systems, rinse until the water runs clear. Ensure no cleaner or chemical residue remains.

Post-Cleaning Maintenance and Storage

After cleaning, inspect all nozzles, filters, and joints for wear or corrosion. Replace any damaged parts before storing your equipment. Allow machinery to air dry entirely before placing covers or storing in enclosed areas to prevent moisture buildup and rust.

For seasonal storage, consider a final light maintenance clean to remove dust or handling marks before you put your equipment away.

The Payoff of a Proper Clean

Regular cleaning of farm machinery prevents corrosion, reduces the risk of chemical cross-contamination, extends the life of high-cost equipment, and keeps your equipment looking good.

Using a strategic process and the proper Econo-Clean dilution levels makes residue removal efficient and effective — no matter how tough the job.